Parquet Versailles Specialist

QUALITY AND GENUINE HISTORY

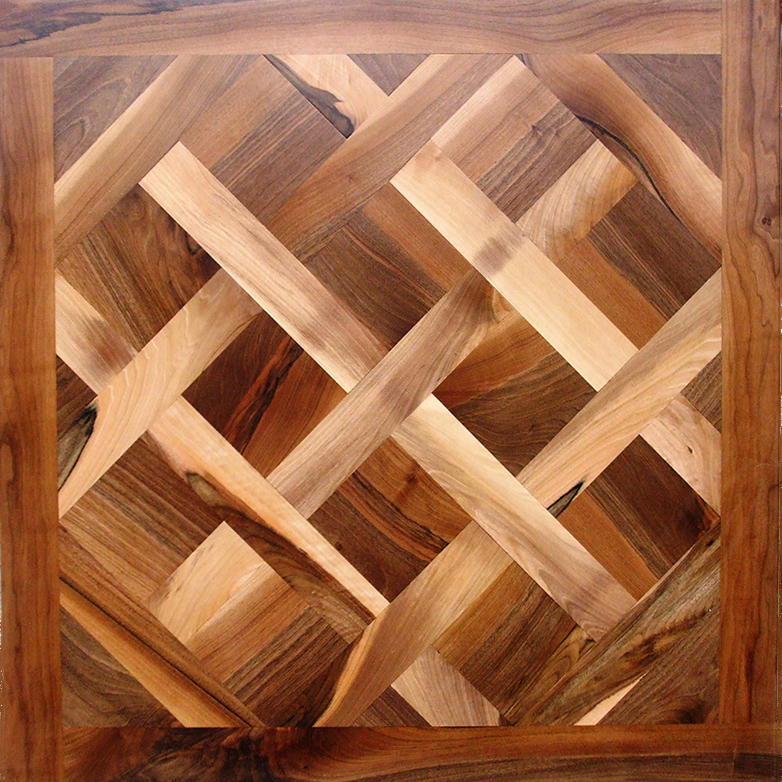

History: "(French parqueterie, from parquet.) The large diagonal squares known as parquet de Versailles were introduced there in 1684, as parquet de menuiserie ("woodwork parquet"), to replace the marble flooring that Walnut Versailles Panelrequired constant washing, which tended to rot the joists beneath the floors. Such parquets en lozange were noted by the Swedish architect Daniel Cronström at Versailles and at the Grand Trianon in 1693".

Floors were highly valued and earned attention at all times. In Europe by the 17th century, masters had achieved perfection producing parquet. Art parquet developed in Europe very fast with the most popular parquet installation technique – "herringbone".

In the 17th century, the most common and famous installations of parquet flooring were "oak brick" and "oak border". Palace and mosaic parquet was Versailles Old Oak Panelspread in 1750 and produced from rare kinds of wood.

Parquet was produced by means of separate panels. Such parquet was called panel parquet. When gluing plank parquet to the panels, two methods were used: marquetry and inlay.

Natural wood color was the most valuable for parquet. The right wood sawn, grading and installation to the neighbor planks under a certain angle made a significant contribution to art parquet. The specific feature of art parquet was the wood changing against the light.

In 17 – 19th centuries, parquet was processed manually only. Factory parquet became widely spread by the 80-ies and eventually art parquet became very rare. Simplicity and grandness are reflected Hand made Versailles Panel with irregularityin many Palaces combining the principle of symmetry with laconic and solemn decoration of the palace interior, making it the marvelous example of the European art parquet. One of the most splendid halls of the palace is the Egyptian Pavilion with its amusing floor. Its central part with enormous medallions is monumental, and the area bordering the center looks very festive. Revival of art parquet began with restoration works. Thanks to a few restoration masters, European art parquet survived till the present days, remaining great art and accurate jewellery work of the true masters. The wood for parquet must be dry. The trees, which were used for parquet manufacturing, were mostly hardwood. The local species like pine, birch,ash and oak are very solid, and not easily worn. To make the wood look voluminous, the wood was fumigated. Another method of wood processing was engraving. The skill to use the grain direction is one of the most important conditions in the production of parquet.

.jpg)